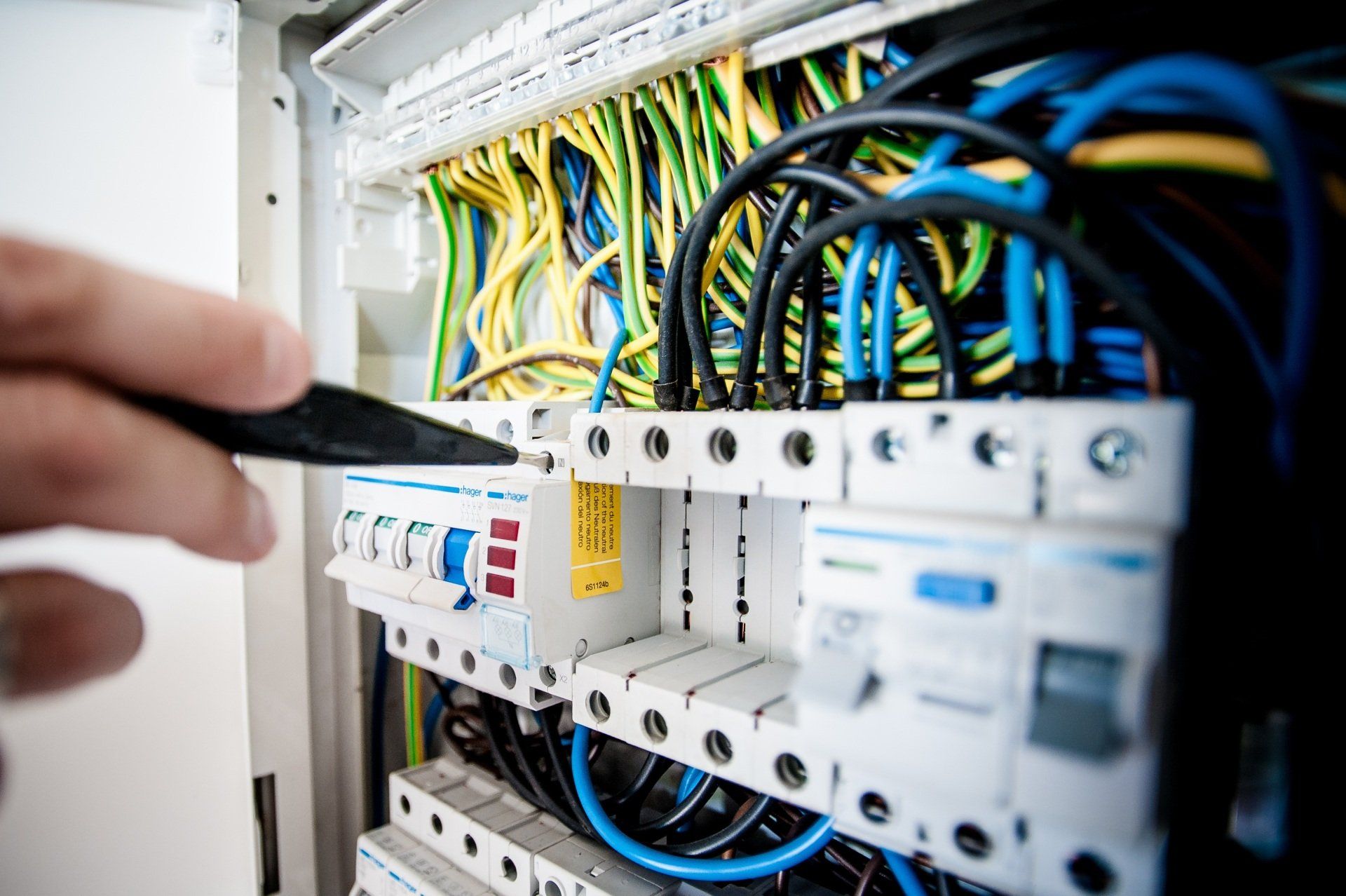

Energy Management, Electrical Installations and Energy Efficiency Improvement.

Energy Optimization

We design, coordinate, and supervise solutions to improve energy efficiency in industrial and mining facilities.

Our goal is to reduce electricity consumption, optimize the operation of energy-intensive equipment, and generate sustainable savings over time.

Through specialized diagnostics, we propose technical improvements, operational reconfigurations, or modernization of electrical installations, prioritizing both efficiency and sustainability.

We offer solutions tailored to each project, with a technical and environmental focus that boosts energy efficiency without compromising productivity.

Let's take care of the planet... Saving Energy

Power Quality and Electrical Safety Diagnosis

Our services go beyond a simple visual inspection. We perform comprehensive power quality analyses that assess compliance with national and international regulations, identify deviations, and propose specific solutions. We measure parameters in both steady and transient states, and we evaluate the entire system from the service entrance to the most critical equipment, ensuring its reliability.

Through specialized diagnostics, we identify causes of failures or efficiency losses that directly affect production, providing detailed reports with technical solutions, recommended protection technologies, and comparative diagrams illustrating the current status and proposed solutions.

Phased Energy Optimization Route

Initial energy diagnosis

We analyze the current state of the facilities, identifying critical consumption, usage patterns, and potential deviations that affect energy efficiency.

Energy opportunity study

We identify areas for improvement, quantify savings potential, and evaluate the technical and economic impact of various optimization alternatives.

Design of technical and economic solutions

We propose a tailored solution with investment estimates (CAPEX) and operating costs (OPEX) as a basis for decision-making.

Planning and detailed engineering

We develop plans, specifications, schedules, and execution logistics to ensure safe, efficient, and technical implementation.

Implementation and technical supervision

We coordinate project execution with functional testing, technical validation, and regulatory compliance at every stage of assembly or adjustment.

Evaluation of results and monitoring

We measure the results obtained, validate the actual savings, and propose adjustments or improvements to maintain energy performance over time.

ELECTRICAL TESTS

- Power Quality Studies

- Network Code Studies

- Power Factor Study

- Harmonic Studies

- Thermographies

- Electrical energy monitoring

- Physical Earth and Lightning Rod Studies

- Short circuit study, protection coordination and electric arc.

Why are they necessary? ✔️ They increase safety and installed load capacity ✔️ They save energy and avoid penalties ✔️ They reduce the risk of failure and production downtime ✔️ They provide access to financial incentives for efficiency

Do you have questions or require information?

DO NOT HESITATE TO CONTACT US