Sustainable management of tailings and water in mining

🎥 Discover how we solve tailings and water treatment challenges.

Tailings and Water Treatment in Mining

Technical solutions that reduce environmental impact, optimize resources, and improve operational safety.

We seek cutting-edge technological solutions for liquid and solid waste management, focused on reducing water consumption, minimizing environmental impact, and optimizing costs.

With advanced thickening and clarification systems tailored to each mining operation, they allow for water recovery, solids concentration, and operation without energy consumption or maintenance.

Through pilot testing, technical validation, and custom design, we turn waste into opportunities for sustainable improvement.

Join us in our mission to build cleaner, more efficient, and responsible mining.

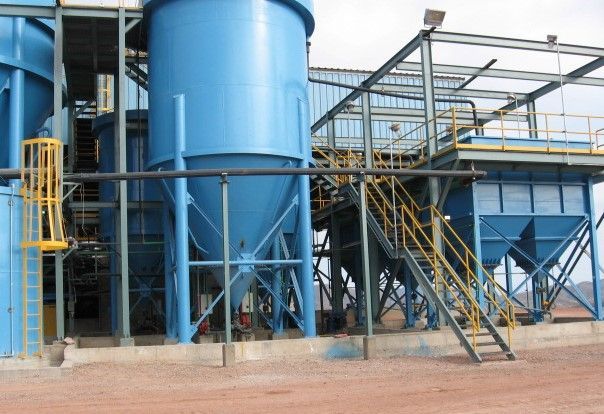

High Solids Thickener IPMC

WHAT IS IT?

The High Solids Thickener is a sedimentation system designed to achieve high solids concentrations without the need for internal mechanisms or electrical power. Its hybrid configuration, which combines a deep cone with inclined plate modules, enables highly efficient, continuous, and maintenance-free solid-liquid separation. This solution eliminates the operating costs associated with motors, skids, and mechanical systems, offering a more reliable, economical, and sustainable operation.

This approach to operation without moving parts and without additional energy consumption not only improves process efficiency, but also increases operational reliability by eliminating critical points of failure and reducing the need for ongoing maintenance.

HOW DOES IT WORK?

The process begins with the pulp being fed into the upper central section of the equipment. The geometry of the equipment allows the solids to settle in the deep cone, resulting in a high solids concentration. The unique feature of this system is that it achieves this sedimentation without the need for additional mechanisms; the solids move naturally to the bottom of the cone.

Results of up to more than 85% solids* of the thickened fraction are achieved.

The water moves toward the surface of the tank, passing through a clarification system that uses inclined plate modules. These modules are capable of promoting the sedimentation of fine particles in the water, resulting in high-quality, clear water. This process ensures effective separation of solids and liquids, recovering over 90% of the water for reuse.

*The result may vary depending on the rheological characteristics and particle size distribution.

Applications

- Tailings thickening

- Concentrates

- Countercurrent washing systems (CWS)

- Process water treatment

- Mine water treatment

Custom Design

Each thickener is sized using a standardized testing methodology: laboratory, mini-pilot, and field pilot. This process allows for precise adjustment of the settling parameters and rheological behavior of each fluid, ensuring an efficient, safe design tailored to each industrial or mining operation.

ADVANTAGES

- 🌱Zero energy consumption

- ⚙️ No mechanisms or moving parts

- 💸Reduction of operating and investment costs

- 🔄 Greater efficiency in water recovery

- 🛠️ Minimum maintenance

- 🧩 Custom design according to your processes

- 🏗️ Smaller construction footprint

IPMC HIGH RESOLUTION CLARIFIER

WHAT IS IT?

It is a device that focuses on the clarification of recovered water or fresh water. These devices are used to treat low-density pulps containing less than 5% solids by weight, with the goal of obtaining completely clear water, with a concentration of suspended solids less than 100 parts per million (ppm).

Clarifiers are characterized by incorporating clarification modules into their internal design, which are essential for carrying out this water purification process.

HOW DOES IT WORK?

The clarifier is made up of two bodies, a square body and a conical section at the bottom.

The pulp feed is located in the upper central part of the equipment. The geometry of the equipment allows the solids to settle in the conical body and these are discharged in the lower part of the cone without requiring any mechanism. The water moves towards the surface passing through a clarification system using plate modules, which cause the fine particles to settle, obtaining good quality water.

Custom Design

Each unit is sized using a standardized testing methodology: laboratory, mini-pilot, and field pilot. This process allows for precise adjustment of the sedimentation parameters for each fluid, ensuring an efficient, safe design tailored to each industrial or mining operation.

Applications

- Treatment of recovered process water

- Fresh water treatment

ADVANTAGES

- 🌱 Zero energy consumption

- ⚙️ No mechanisms or moving parts

- 💸 Reduction of operating and investment costs

- 🔄 Greater efficiency in water recovery

- 🛠️ Minimum maintenance

- 🧩 Custom design according to your processes

- 🏗️ Smaller construction footprint

Comprehensive Testing and Custom Design Process

From the laboratory to industrial design, we ensure performance, efficiency, and measurable results.

Laboratory tests

We conduct initial laboratory tests using test tubes and basic physical and chemical analysis. At this stage, we evaluate key parameters of the water or suspension, select the most suitable reagents, and define the type of treatment required to achieve efficient separation.

Mini Pilot Test

We tested reagents, retention, and sedimentation in a mini pilot plant to precisely adjust dosage and validate process viability.

Pilot Test

Before design and manufacturing, we check that it works.

With field pilot testing using a mobile plant to ensure each solution delivers real efficiency and validated performance from the start.

We use a standardized methodology for testing and sizing thickening and clarification equipment, adjusting parameters based on the rheological and settling properties of each fluid type. This ensures a precise and efficient design for any application.

Sustainable Pasta Dams

Beyond thickening: Towards safer and more sustainable tailings dams

Paste dams represent a modern, safe, and cost-effective alternative to traditional tailings storage. Through the use of high-performance hybrid thickening technology, a high solids concentration is achieved, minimizing water content and increasing stability.

The thickened material can be dry stacked, providing greater geotechnical stability, water recovery for recirculation, and a significantly smaller environmental footprint. This solution meets regulatory, social, and environmental requirements, aligning with the principles of sustainability and responsible mine closure.

🚚 Handling and Transporting Pasta

The pastes generated by the thickening system can be transported using various technologies, depending on the concentration level and operating conditions:

- 🔄 Progressive cavity pumps: Ideal for high-concentration pastes with relatively simple paths.

- ⚙️ High-pressure piston pumps: Recommended for very high-density pastes and complex routes.

- 📤 Conveyor belts: An efficient alternative for medium distances and dry stacking.

- 🚚Hauling systems: Used in cases where pumping is not feasible or greater logistical flexibility is required.

These options are adapted to the geographic and topographic characteristics and needs of each mining operation, ensuring operational continuity, cost efficiency and reliability in the final disposal of tailings.

Benefits

- 💧 Water savings: Recovery of up to 90% of process water.

- 🏔️Geotechnical stability: Lower structural risk in dams.

- 🌱Sustainability: Reduced visual and environmental impact at mine closure.

- 📊CAPEX/OPEX Reduction: Lower transport volume, without the need for hydraulic dams.

- 🛠️ Comprehensive design: From the thickener to final disposal

Specialized Complementary Services

Beyond thickening: Towards safer and more sustainable tailings dams

| Our additional services include: | ||

|---|---|---|

| ✓ Design and integration of paste production systems for tailings dams and mine backfill. | ||

| ✓ Engineering of pumping systems for pastes and recovered water. | ||

| ✓ Execution of pilot tests for thickening and solid-liquid separation. | ||

| These solutions are tailored to the specific requirements of each mining operation, ensuring efficiency, sustainability, and measurable results. |

Success Stories Thickening System

GUANACEVÍ MINING

THICKENING OF LEACH TAILINGS

COSALA MINING

THICKENING OF FLOTATION TAILS

LA PARRILLA MINING

THICKENING OF FLOTATION TAILINGS AND LEACH TAILINGS

COSALA MINING

THICKENING OF CONCENTRATES

Success Stories Clarification System

MINING THE EDGES

FRESH RIVER WATER CLARIFICATION SYSTEM FOR USE IN PROCESSES AND SERVICES.

COSALA MINING

CLARIFICATION OF RECOVERED WATER FROM LEAD, COPPER AND ZINC CONCENTRATES.

Success Stories: Field Pilot Tests

LA NEGRA MINING

MOBILE PILOT PLANT

LOW FLOW PILOT THICKENER WITH RESULTS OF 82% SOLIDS IN THE FLOTATION TAILS

EL MONTE MINING

MOBILE PILOT PLANT

THICKENING TESTS ON FLOTATION TAILS AND CONCENTRATES

"Solutions for the treatment of water and mining waste."

Contact us for more information.